Underwater cleaning of ships hull. Cleaning and polishing of propellers

Today the biochemical corrosion which causes great harm to the ship’s hull and other marine facilities gives a lot of anxiety to the shipowners.

- Advantages of underwater hull cleaning.

- Hydrodynamic cavitation method.

- The method of mechanical cleaning using hydraulic metals.

- FAQ to the topic: “Underwater cleaning of ships hull. Cleaning and polishing of propellers”.

- Ship’s weight decreases, hence manoeuvrability and speed increase;

- Surfaces are ready for inspections or repair works;

- Fuel oil consumption decreases;

- Ship’s total lifetime increases.

- Increase the life of the hull and its propellers.

- Reduce the risk of accidents at sea.

- Increase fuel saving.

- Increase ship speed.

- Reduce engine load and slow down wear.

- After the ship returns after a long voyage.

- With a noticeable decrease of a ship speed and increased fuel consumption.

- With a decrease the efficiency of cooling system on board.

- Before conducting planned underwater inspections.

The hull bottom of the ship which returns from a long voyage looks like a huge “settlement”, colony of algae and other marine organisms. In spite of the up-to-date means designed to protect the ship against fouling, the similar outgrowth can be 500 millimeters in thickness and sometimes even more. The speed loss is 30% of the rated one, herewith the fuel oil consumption increases by the same amount. The regular underwater cleaning of the ship makes it possible to restore the initial speed by 95-98% and respectively to decrease the fuel oil costs which, as a rule, account for almost half of the operating costs. It is also advisable to clean and polish the propellers: firstly, decrease of cavitation which destroys the surface of propellers, secondly, saving effect the same as while cleaning and sometimes even more. That’s why the ship’s hull underwater cleaning, cleaning of the sea valves gratings and other structural members are so demanded today all over the world.

Advantages of underwater hull cleaning

The underwater cleaning of hull, cleaning of propeller, cleaning of sea valves gratings and other structural members subjected to fouling do not require docking today. The scheduled underwater cleaning of the hull is very economically advantageous during the inter-docking period, for example, such measures can save up to 900 t fuel oil/year for a shipowner having tanker of 50 t displacement. Here is a brief list of efficiency of such procedure as the underwater cleaning.

The up-to-date underwater cleaning of the ship’s hull is carried out by new effective methods but without rejecting the old time-tested.

Hydrodynamic cavitation method

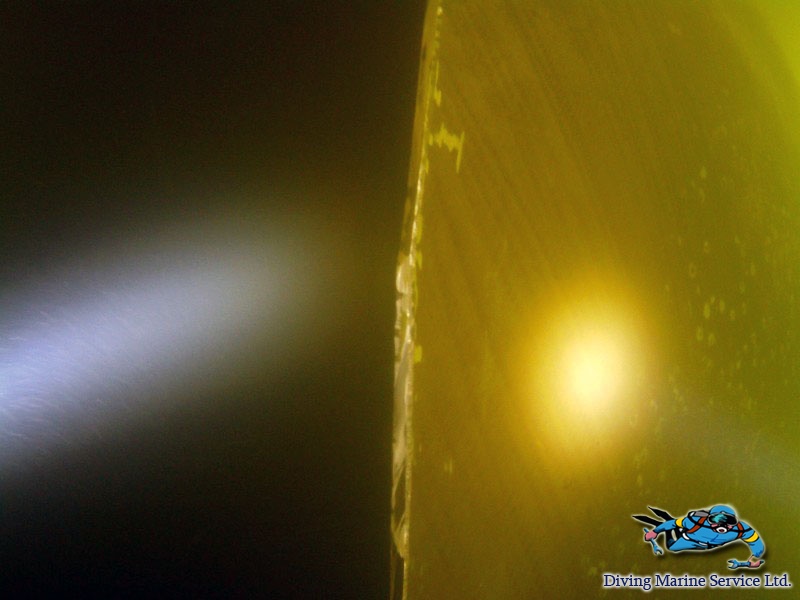

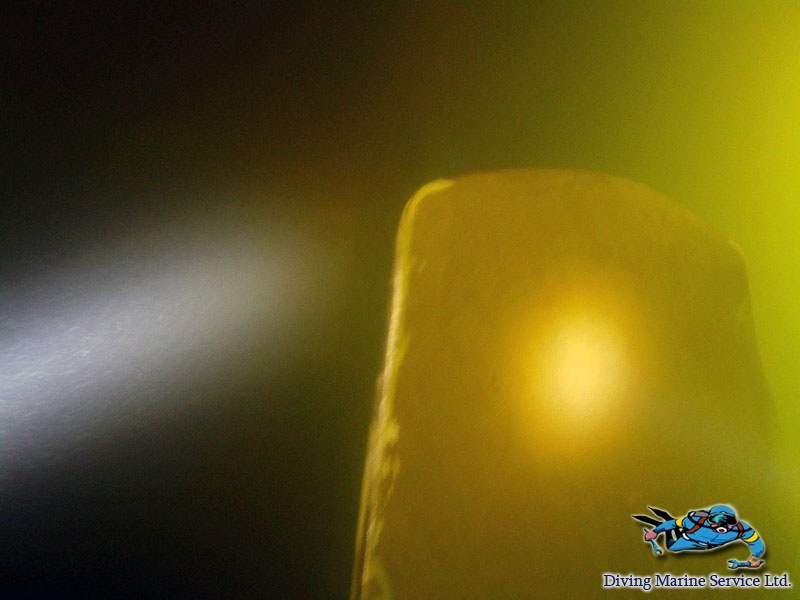

Method of the hydrodynamic cavitation removes the fouling from the ship’s surface maintaining its varnish-and-paint coating. This method makes it possible to carry out the underwater cleaning where it is impossible to do it by mechanical method. The hydrodynamic cavitation is effective where it is required the cleaning of the vent distribution ducts, sea chest gratings, sea chests, valves and so on. The hydro-cavitation as a technology goes back by its origins to ancient 1894 year, and a copyright belongs to Froude, an English engineer. As a simple example of cavitation, normal boiling water when the steam pressure is equalized with the environment pressure and there are bubbles which flow to the zone of more high pressure. With this motion the bubbles seem to slam creating a strong shock wave. The principle of operation of the plant for the hydro-cavitation cleaning is based on the strength of high impact jet which is delivered under certain pressure. Steam-gas bubbles, coming to the surface which should be cleaned, collapse. Arising from this the shock wave cleans the hull and other structures against rust and fouling. The underwater cleaning of hull by means of the hydro-cavitation plant removes all without exception types of fouling, rust, paint; and its another advantage is that hydro-cavitation equipment has its absolute environmental safety.

The method of mechanical cleaning using hydraulic metals

Method of the mechanical cleaning by means of the hydraulic metals is indispensable in case of heavy degree of fouling as well as when the ship should be cleaned very quickly during the ship’s stay at anchor or in port. The underwater cleaning by means of the hydraulic metals and by using the hydraulically-driven brush-machine is based on the action of the rotating machine equipped by a special brush, and the brush, in its turn, is driven by the hydraulic motor. Coaxial hose supplies the hydraulic liquid from the pump station arranged above water. Special design of the brush makes it possible to fit tightly like sticking to the surface being cleaned. Brushcarts-brushes can clean both the horizontal and vertical surfaces and can also remove practically all existing types of fouling (shell molluscs, algae and others). The hull main coating is not subjected to risk of damages in spite of rather powerful effect onto the surface of machine. This is owing to the special materials of which the brushes are made. The level of brush hardness is also selected depending on the type of fouling, so the varnish-and-paint coating is not practically damaged.

FAQ to the topic: “Underwater cleaning of ships hull. Cleaning and polishing of propellers”

What is the hull cleaning?

Cleaning the hull of a ship is the process of removing corrosion products, old paintwork, fouling by algae and marine organisms from the hull of a ship what is carried out afloat (under water) and in the dock. The hull cleaning method depends on the required degree of cleaning and the condition of the shell plating: the nature, thickness and strength of layer the corrosion products, old paintwork and fouling.

Why clean the hull?

Biochemical corrosion, fouling by algae and marine organisms causes great harm to ships. Corrosion is fraught with the appearance of underwater holes through which water can quickly enter the hull and lead to tragic consequences. In turn, growths seriously worsen the running properties of the vessel reducing its speed and increasing fuel consumption by 30%. Thus, regular cleaning of the hull and elimination of corrosion allows the following:

What are the ways to clean the hull?

There are the following methods of cleaning the hull today: mechanical, chemical and thermal cleaning. Each of these methods have its own subspecies and is applied depending on the situation. Herewith the vessel is cleaned under water by a mechanical method including the use of hydrodynamic cavitation. Our company specialists use special equipment – the Brush-Kart system. The Brush-Kart system with three cleaning heads allows to clean up to 1500-2000 m2/hour in strips of 1.25 meters wide and up to 12 meters long.

How the hull is cleaned under the water?

Diving companies use hand tools or mechanical cleaning to clean the hull of the vessel under water, to clean the propellers and sea chests. Diving Marine Service LLC uses hydraulic equipment from Piccard Divers – the Brush-Kart system, what allows quickly dealing to biochemical corrosion.

When is it necessary to clean the hull and propellers of a ship?

It is recommended cleaning the hull and its propellers in the following cases:

Latest news

- Maintenance of fish protection structures 09.05.2020

- Underwater inspection of port and offshore facilities 02.05.2020

- Hull cleaning using Brush-Kart system 18.04.2020